INNOVATIVE TECHNIQUES

Whether it is a question of works in reinforced concrete or in METALLIC CARPENTRY, our expert technical team will find the most suitable solution to the specific needs of the customer; moreover, thanks to the research activity carried out within the company, we are able to intervene through the application of innovative techniques, such as:

HEC BEAMS

The HEC beam is the winning solution that the Marotta Group proposes in construction and infrastructure. The HEC beam makes it possible to reduce the sections normally required for reinforced concrete beams, or, with the same sections, to carry greater loads or have greater spans, and moreover with the complete elimination of scaffolding and form work.

PRESTRESSED STEEL

Prestressing allows to considerably increase the resistance characteristics. This innovative technique allows covering large spans representing, in this way, an optimal solution for the realization of bridges and viaducts.

NUVI SYSTEMS

The spatial grids are modular and made up of highly industrialized elements therefore realized with remarkable dimensional precision and accurate surface finish. The system is particularly suitable for the opening of large spaces where you do not want to give up aesthetics in the respect of the general economy; sports facilities, airport hangars, exhibition structures, large industrial sheds, concessions halls and stadium covers are just some examples of applications.

BRBF BRACING

The need to improve or adapt seismically public and private buildings following seismic events of medium-high intensity, which are approaching with increasing frequency, makes the BRBF technology (BUCKLING RESTRAINED BRACED FRAME) with dissipative steel braces, among the most performing, efficient and low cost. This technology allows the insertion of dissipative braces in the external, internal or visible curtain walls without interrupting the activities in the building and in a very short time.

BETON PLAQUE' AND PILLARS CASING WITH PERFORMANCE CONCRETE AND REINFORCED

One of the simplest and cheapest technologies, with guaranteed results, is the Beton Plaquè. In practice, with the use of epoxy adhesives, steel plates are glued to the existing beams (in some cases also to the columns) to ensure the right area of reinforcement necessary to absorb the stresses of the standard: bending moments and shear. In addition to the beton plaquè, where the sections are undersized for stiffness, it is used to roughen or embed these sections, usually the pillars, with mortars or performance concretes with high mechanical properties and addition of reinforcement for bending and shear.

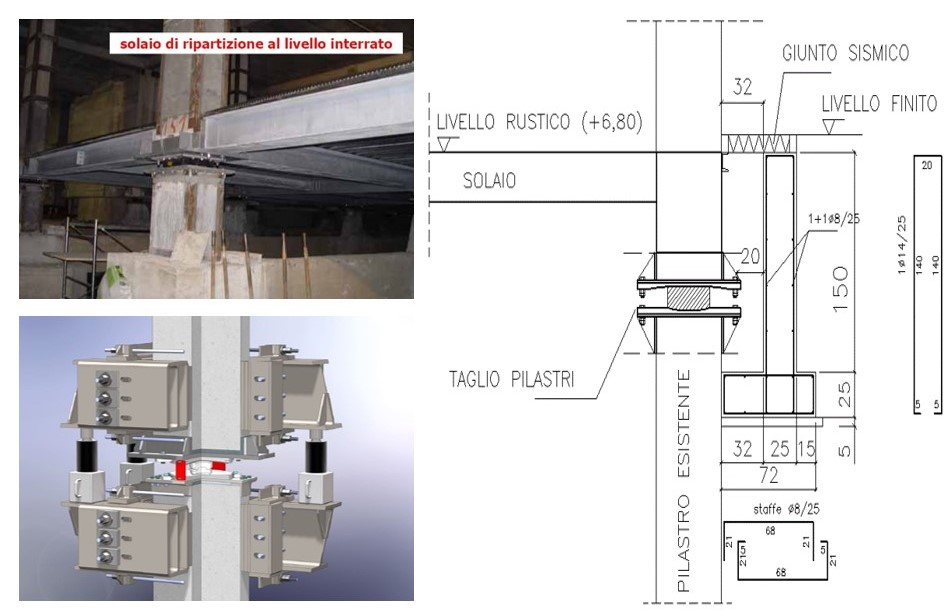

SEISMIC ISOLATION

This technology has become today one of the most efficient techniques to isolate the structure and dissipate seismic energy without the structure itself suffering any damage, even during high intensity earthquakes. The seismic isolation at the base is also applied for the Seismic Adaptation of existing buildings or damaged by previous earthquakes. The techniques for inserting seismic isolators (and dissipaters) into existing structures are fast, safe, reliable and economical.

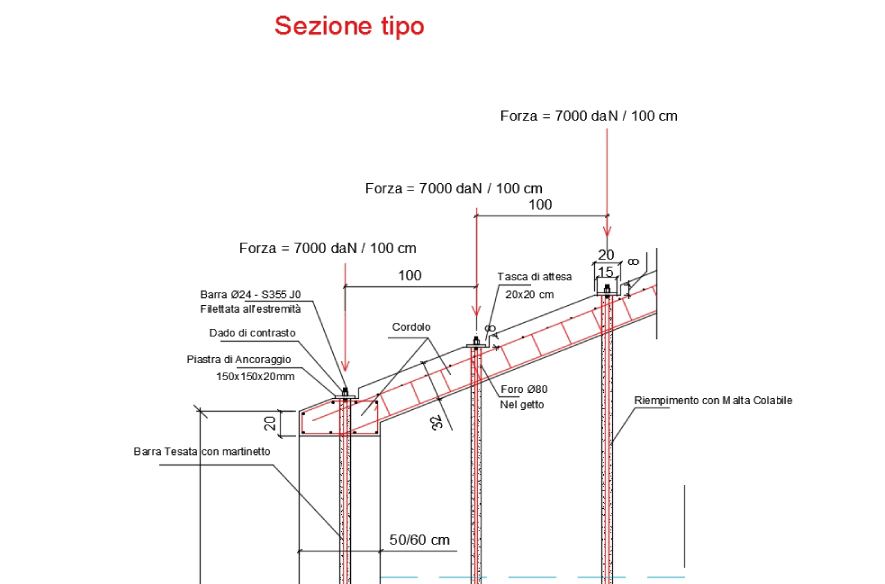

REINFORCED AND PRE-STRESSED MASONRY

The original system of “reinforced and pre-compressed masonry” is an innovative technique of Marotta Group that allows to improve seismically any masonry building, including historical and frescoed walls, without intervening inside, safeguarding the content. This means not to undertake any construction activity inside the building, to protect floors, walls, ceilings, frescoes, accessories, decorations of inestimable artistic, historical, religious value.